SRS Group is proud to partner with Ronstan Tensile Architecture, a global leader in tensile architecture and rigging solutions whose precision-engineered cable systems integrate seamlessly with SRS’s installation expertise on New Zealand’s most demanding projects. This collaboration delivers minimalist, high-performance barriers that prioritise safety, transparency and longevity in commercial and public spaces.

Introducing “Vertical Cable Safety Barriers”

Continuing our series on Ronstan’s thought leadership, SRS is sharing the whitepaper “Vertical Cable Safety Barriers – Principles for Good Design,” which demystifies the specialist field of tensioned stainless steel cable barriers for atria, voids, balconies and stairs. The paper stresses that while Australia’s National Construction Code (NCC) offers basic “deemed to satisfy” guidance, true compliance and durability demand a deeper understanding of cable behaviour, connections and load transfer to building structures.

Common pitfalls in cable barrier design

The whitepaper highlights risks like non-articulated end fittings that cause bending or vibration under load, leading to premature failures even if initial NCC checks pass. Other issues include inexperience with cable performance, cost-cutting on swaging processes, mismatched materials for site conditions and inadequate maintenance planning, any of which can render a barrier non-compliant or unsafe over time.

The critical role of articulated connections

End fittings must articulate to allow free movement under point loads, like a person leaning or falling, preventing bending at terminations and ensuring cables reach their ultimate resistance before any deformation occurs. Options such as Belleville washers, ball fittings and pinned connections provide this rotational freedom, aligning with international standards like Eurocode 3 Part 1-11 and ASCE19-16 that emphasise fatigue resistance, corrosion protection and preload stability.

Beyond NCC: Engineering for real performance

For spans over 2500mm, NCC deemed-to-satisfy rules don’t apply, requiring first-principles engineering, deflection testing and potentially horizontal clamps to control movement without overloading slabs or soffits. Cable selection should prioritise low-stretch constructions like 1×19 strands for stiffness, with full consideration of environmental factors, strength and ductility to match the application.

Lifecycle costs and maintenance realities

Non-articulating fittings demand rigorous, ongoing inspections and immediate cable replacements, adding significant lifecycle expenses that should be budgeted upfront by all stakeholders. Proper design with articulated systems minimises these risks, ensuring barriers maintain compliance, safety and aesthetics throughout the building’s service life.

Ronstan’s expertise – powered by SRS delivery

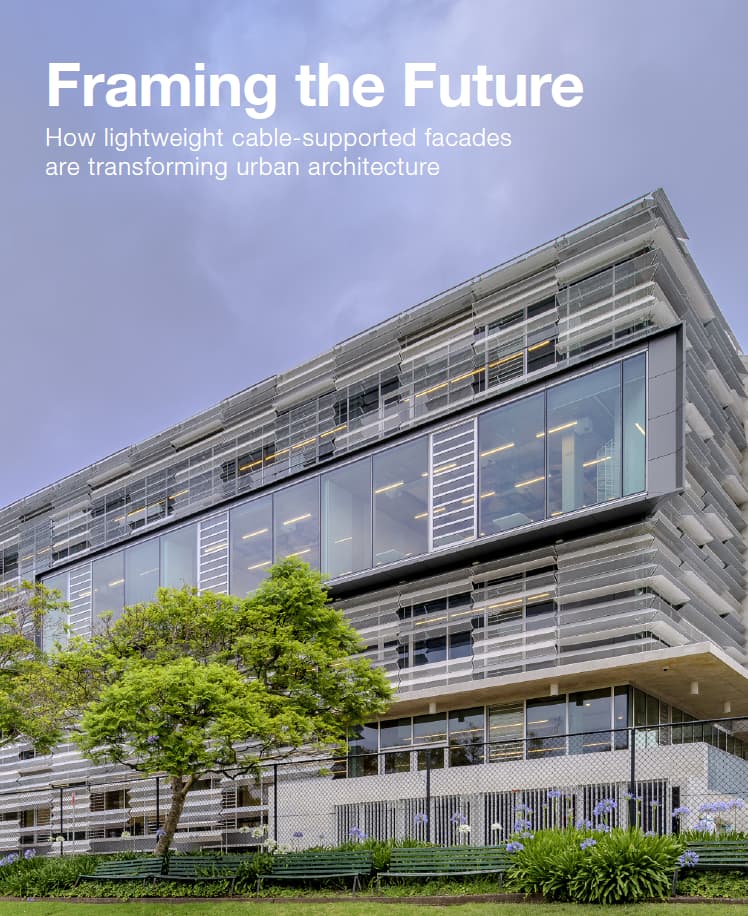

Ronstan brings decades of tensile innovation, from ACS3 stainless steel cables to Carl Stahl I-SYS® fittings, offering end-to-end design, analysis and build guidance that exceeds NCC basics. Paired with SRS’s local installation prowess on projects like University of Auckland HIWA, this means clients get barriers that are not just compliant, but built to last and look striking.

For detailed specs, connection options and design checklists, follow the link to Ronstan’s full “Vertical Cable Safety Barriers – Principles for Good Design” whitepaper.