Types of metal fabrication processes

Metal fabrication is a broad term referring to any process that cuts, shapes, or moulds metal material into a final product. From appliances and light fixtures to desk tools, chairs, and utensils, metal is the stabilising element that makes all of today’s conveniences possible.

There are many different metal fabrication processes and the process used depends on both the beginning metal material and the desired end product. You can find out more about the metals we use at SRS in our custom metal fabrication jobs in our recent post. Some of the most popular metals used in metal fabrication work include:

- Stainless steel

- Mild steel

- Aluminium

- Corten steel

- Brass

- Copper

Other metals that can be used in fabrication work include gold, silver, nickel, iron, tin, and titanium, however, these are less commonly used for the custom metal fabrication work carried out by SRS.

What are the different types of metal fabrication?

As we’ve already touched upon, metal fabrication involves a number of different processes in order to take a raw metal component, such as sheet metal, metal rods, metal billets, and metal bars, to create a new product.

At SRS, we are one of New Zealand’s leading metal fabrication companies, producing high-end, bespoke fabrication work for businesses and individual across New Zealand. With a trusted team of experienced in-house quantity surveyors (QS), project managers, CAD designers and metal fabricators, we can take care of the complete fabrication process from start to finish.

Here are some of the metal fabrication processes used by the team at SRS to create bespoke metal products for our customers:

Cutting

One of the most versatile and commonly used metal fabrication processes is cutting. On the surface, the process is nothing more than cutting large pieces of metal into smaller ones.

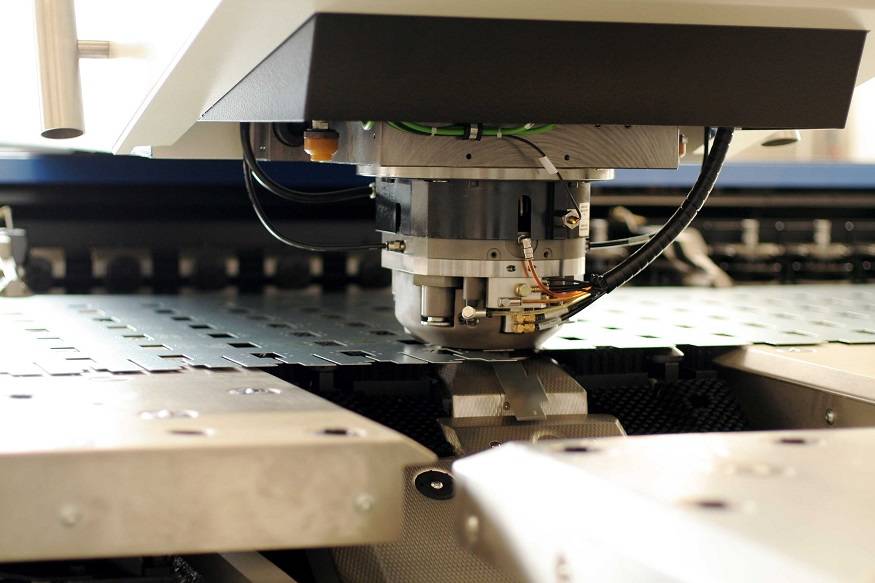

Cutting is quite intricate and involved, however. Technology like lasers, waterjets, power scissors, and plasma are all utilised to create exacting cuts.

Depending on the project, cutting is often the first, if not only, process used in fabrication.

Folding

One of the more complicated processes of metal fabrication involves folding, where a metal surface is manipulated to shape at a certain angle.

With certain folding applications, the intent is to make the metal surface fold at a 90-degree angle, or something else that’s either more or less blunt. The most common means is with a brake press that creates creases in the metal by pinching it.

However, folding may only be performed in facilities that are equipped with specific, high-tech equipment due to the complexity of the whole process. In many cases where a fold is needed, the joining of two metal panels at select angles would be the more practical alternative.

Welding

Welding is the art of adjoining two or more pieces of metal through a mixture of heat and pressure. This process is most common in large scale or industrial fabrication projects.

It’s popular because various pieces of metal can be conjoined no matter their shape or size. The parts used in a welding application could be sheets, panels, bars, or shapes — as long as the parts are made of metal, it really doesn’t matter.

Depending on the project, the most common types of welding include MIG, stick and arc, TIG, and flux-cored arc. You can find out more about the different types of welding we use at SRS and what they are used for in a recent blog.

Machining

Machining refers to the process of shaping metal by removing the unwanted material from it. This process can be performed in a variety of ways. There are many different machining processes, including drilling, turning, and milling.

Typically, the process is performed on a lathe, which will rotate the metal against tools that trim corners and edges to cut the piece down to a desired shape or measurement.

Milling is also very common among the metal fabrication processes by which multi-point cutting tools remove metal from the workpiece. CNC machines are also used for this process which normally functions as a final finish process to create a desired texture or appearance.

Punching

When holes are formed in a piece of metal, the process involved consists of punching, where metal is placed under a die and submitted to a punch-through by a drill.

For the punch to be the correct size, the circumference of the drill must slot correctly through the die. Punch presses have specially designed turrets that hit the metal through a die to produce holes in specific locations.

Punching is used in both light and heavy metalwork.

Stamping

This process is similar to punching, except the press doesn’t create a hole in the metal, but an indentation.

For applications like these, the process of stamping is used to form certain shapes, letters or images within a metal sheet or panel. In effect, metal stamping is similar to relief carving in wood or marble.

A primary example of metal stamping is seen on coins, where words, currency amounts and the faces of presidents are stamped from each surface side on pennies, nickels, dimes and quarters.

Shearing

For sheets of metal that require long cuts, the process is known as shearing. In some cases, the sheet is fed horizontally through a metal-cutting machine. In other applications, a cutting tool is applied vertically against the length of a flat metal sheet. A third method involves placing the metal over the edge of an open cutter and lowering the blade, much like the paper cutters found at copy facilities.

Shearing is often applied to trim down the edge of a metal sheet, but the process may be done anywhere along the metal.

It is ideal for cutting smaller lengths and differently shaped materials since the blades can be mounted at angles to reduce the required force.

Forging

Forging is a common practice for intricate metalwork. Forging uses compressive force to shape metal.

Done by hand, forging involves heating metal to the point that it can be bent, shaped, and formed with the use of a hammer or die strikes. Forging can also be carried out with the metal at room temperature and this is called cold forging.

One of the oldest forms of metal fabrication processes in existence, forging is still widely used by blacksmiths and fabricators for detailed and artistic work to this day.

Casting

Whereas forging metal is something that’s done by hand, casting is the process of pouring molten metal into a mould. From there, it’s cooled to the point that it becomes hard.

Casting is widely accepted as the go-to process for mass-produced products where the same mould can be used over and over again with minimal variance in the final outcome.

Like forging, casting is also one of the oldest types of metal fabrication and can be applied to a variety of metals including steel, iron, gold, copper, silver, and magnesium.

Extrusion

During extrusion, metal is forced between an opened or closed die. Here, the piece of metal is reduced to the cross-section of the die. As a result, a cavity is formed. Extrusion can be continuous to create very long pieces, or semi-continuous in order to create many shorter pieces.

Also called cold extrusion, impact extrusion is performed at room temperature and increases the strength of the part, making it stronger than the original material.

Hot extrusion is performed at an increased temperature, to keep the metal from hardening and to make it easier to push through the die. The resulting cylindrical item product is often wiring or piping.

SRS – your go-to for commercial fabrication

Architects and designers often approach us to solve tricky commercial fabrication problems, and we’re happy to help. At SRS, on top of our green wall, rigging and fabrication solutions, we offer a number of complementary services for the commercial market – all of which are more cost-efficient because they’re delivered in-house.

On occasion, architects will come to us for just our fabrication services. Our first in-house fabricator joined the SRS team in 2016 to craft planter boxes for our green façade and screens. Today, our fabrication team has grown to fifteen people, and our creations span much further than green wall planter boxes.

Get in touch with the team today and find out how we can meet your metal fabrication needs.